We are excited to announce that our Process Engineer Yi Han Hsu, MSc will be presenting at the China ALD Conference 2025 in Guangzhou, November 15 on a breakthrough in atomic layer deposition (ALD) for lithium-ion batteries. Lithium fluoride (LiF) thin films are emerging as highly effective protective coatings for battery electrodes due to their exceptional electrochemical and chemical stability. Traditional ALD methods, however, often face challenges such as high deposition temperatures, contamination, and reliance on hazardous co-reactants.

In the presentation, she will introduce a novel plasma-enhanced spatial ALD (PE-sALD) process using an innovative lithium precursor. This low-temperature, sustainable approach produces ultra-pure LiF films, free from carbon and oxygen impurities, making it ideal for coating complex, porous electrode materials.

She will also discuss how this technology improves the performance of graphite, silicon, and LMNO electrodes, while enabling scalable, roll-to-roll manufacturing. This work represents an important step toward cleaner, high-performance Li-ion batteries and highlights the potential of advanced ALD techniques for industrial applications.

We look forward to sharing our findings with the ALD community in China during the China ALD Conference in Guangzhou, November 14-16, and exploring collaborations that advance the next generation of battery technologies.

November 15, 2025

Session 3: ALD for industry

14:25-14:50

China ALD Conference, Hilton Hotel, Room M5

Authors

Joost van Himste, Niels Hoogendoorn, Paul Poodt – SparkNano Jamie Greer, Nicolas Blasco – Air Liquide Advanced Materials

Low Temperature Spatial Atomic Layer Deposition of LiF Films for Li-ion Batteries

Abstract

Lithium fluoride (LiF) thin films have gained significant attention as protective/passivating layers for Li-ion battery electrodes due to their wide electrochemical stability window and excellent chemical stability. When deposited using highly conformal methods like atomic layer deposition, LiF can effectively coat the complex, porous structures of battery electrodes to improve their electrochemical performance and stability. Several combinations of Li precursors and co-reactants for LiF deposition have been explored in the literature. However, these processes often require high deposition temperatures and yield films with notable contamination from oxygen (O), carbon (C), or silicon (Si). Furthermore, the low volatility and reactivity of many Li precursors, combined with the use of greenhouse gas- and PFAS-based or otherwise hazardous co-reactants (e.g., SF₆, CF₄, or HF), pose challenges to the applicability, sustainability, and scalability of reported ALD processes.

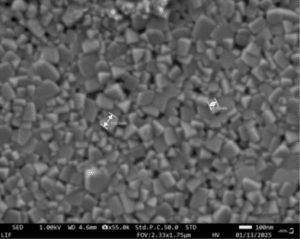

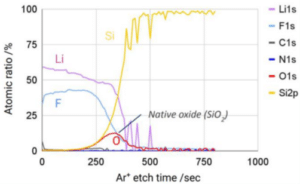

To address these limitations, we present a newly developed plasma-enhanced spatial ALD process employing a novel Li precursor named LIFA (Air Liquide Advanced Materials). This approach eliminates the need for greenhouse gas-, or otherwise hazardous co-reactants. Pure LiF films have been successfully deposited at temperatures ranging from 100°C to 200°C, making the process compatible with deposition on Lithium metal anodes. The films exhibit a growth per cycle of 0.04–0.05 nm/cycle and a refractive index of 1.36–1.39 at 633 nm. Characterization via XPS, XRD, and SEM confirms that the films are polycrystalline, highly pure, free of C and O contamination, and stable in ambient conditions.

These LiF films demonstrate excellent conformality on porous substrates and have been applied to various anode and cathode materials, including graphite, silicon, and LMNO, where they have shown significant improvements in electrochemical performance. Additionally, we outline our approach to scaling up the process for industrial-scale manufacturing using high-speed, atmospheric-pressure roll-to-roll spatial ALD. The combination of this sustainable and efficient LiF deposition process with high-speed spatial ALD presents a promising avenue for the mass production of high-performance Li-ion batteries.

Supporting information:

Figure of SEM image of a 62 nm LiF film

Figure of XPS spectrum of LiF on a silicon substrate

About the speaker

Yi Han Hsu is a seasoned process engineer at SparkNano, bringing extensive expertise in advanced manufacturing. Yi Han earned a Master’s in Material Science from National Chiao Tung University (Taiwan) before starting here career in the semiconductor industry at TSMC. She later completed a Master’s in Sustainable Energy Technology at Eindhoven University. Following this, Yi Han spent seven years at Schunk Xycarb Technology, refining CVD SiC coating processes, and subsequently joined SparkNano this year to drive innovation in next-generation sustainable technologies through spatial ALD coating technology.

About the China ALD Conference (C-ALD)

Atomic Layer Deposition (ALD) technology, as a precise thin-film fabrication method at the nanometer and sub-nanometer scale, offers exceptional control over film thickness at the atomic level, as well as unique structural and performance characteristics. With its advantages of near-chemical stoichiometry and relatively low processing temperatures, ALD has been widely applied in microelectronics, optoelectronics, catalysis, energy, optics, corrosion resistance, and biomedical materials.

To explore the latest research achievements, applications, and development trends in ALD technology, and to promote academic exchange and collaboration, China ALD 2025 (C-ALD) will be held. This conference is co-organized by Fudan University and Tongji University, with support from Sun Yat-sen University’s School of Materials Science and Engineering, Shanghai Xiangsheng, and Jiangsu Ade Technologies.

The event will take place from November 14 to 16, 2025, in Guangzhou, China, featuring invited talks, oral presentations, and poster sessions.